哪些因素会导致晶振产品特性受影响

来源:http://www.taiheth.com 作者:泰河电子晶振 2019年03月29

在晶振使用或者是晶振焊接过程中,都会遇到许许多多的问题,焊接问题有时候会焊接不上,晶振产品挂不住在板子上,渥焊,假焊都是有可能的.晶振焊接上去带不动板子正常工作,又或者焊接过程中的失误导致晶振在焊上板子之后偏差太大.

In the process of using crystal or crystal welding, there are many problems encountered. Welding problems sometimes cannot be soldered. Crystal products can't be hanged on the board. Soldering and false soldering are all possible. The normal operation of the plate, or the mistakes in the welding process, cause the crystal to deviate too much after welding the board.

在这里,泰河电子为大家整理了一份关于晶振产品的产品特性以及影响产品特性的因素,以供大家参考使用.喜欢的可以收藏起来后续再看.

Here, Taihe Electronics has compiled a product characteristic for the crystal product and factors affecting the product characteristics for your reference. You can collect it and follow it later.

首先是我们比较关心的常温产品特性:常温产品特性有时也称为室温产品特性,一般是指产品在环境温度为25℃,相对湿度为50%左右时所测量出来的电性能参数,主要是频率,电阻,激励功率相关性及电容比等指标。

First of all, we are concerned about the characteristics of normal temperature products: normal temperature product characteristics are sometimes called room temperature product characteristics, generally refers to the electrical performance parameters measured when the product temperature is 25 ° C, relative humidity is about 50%, mainly frequency , resistance, excitation power correlation and capacitance ratio indicators. 常温下石英晶振产品的频率主要是观察其稳定性与一致性。稳定性是相对于单个产品而言,一方面要求产品在测试仪上重复测试时,频率变化量要小,好产品频率变化量可以小于±0.5ppm,与产品频率高低及TS大小有关,一般情况下,频率越高变化量越大,TS越大变化量越大,测量指标一般是FL,若是FR则不存在TS的问题;另一方面要求产品在电路中工作时不出现频率漂移,也就是说产品频率不要跑到几百甚至几千ppm去,一般情况下只有高频(27M以上)产品才会有这个问题,尤其是3RD产品。

The frequency of the product at room temperature is mainly to observe its stability and consistency. The stability is relative to a single product. On the one hand, when the product is repeatedly tested on the tester, the frequency change is small, and the good product frequency variation can be less than ±0.5ppm, which is related to the product frequency and TS size. The higher the frequency, the larger the amount of change, the larger the TS is, the larger the change is. The measurement index is generally FL. If it is FR, there is no TS problem. On the other hand, the product does not have frequency drift when working in the circuit. Say that the product frequency should not go to hundreds or even thousands of ppm. Under normal circumstances, only high frequency (27M or more) products will have this problem, especially 3RD products.

如果频率不稳定,偏移的幅度上百ppm或同时伴有C0偏小现象,应考虑胶点是否松动。

If the frequency is unstable, the amplitude of the offset is hundreds of ppm or accompanied by a small C0 phenomenon, it should be considered whether the glue point is loose.

对于一条相对成熟的生产线来说,产品在常温下的频率稳定性一般不会出现问题,比较常见的是产品的一致性(散差),尤其是高频的小公差产品一致性往往不如人意。一致性考虑是多个产品的频率公差,在测试系统中,观察FL的正态分布图可以很直观的了解产品的一致,也可以使用仪器测试系统中的CPK计算功能,通过CPK来衡量产品的一致性。

因烤胶时间或温度不正确也会造成频率散差大,只是出现的概率较小,芯片原因造成频率散差大一般在微调工序就能反映出来。为比较及时的了解频率的一致性,应在封焊工序增加一个抽检工站,以考查微调封焊后状况,尤其能较早发现微调范围或微调人员的个体差异。分析原因时一定要考虑各批次产品在制程中流动的时间是否大致相同,且越短越好,这一点对于产品的DLD特性也影响很大。

Due to the incorrect baking time or temperature, the frequency dispersion will be large, but the probability of occurrence is small. The large dispersion of the frequency caused by the chip is generally reflected in the fine adjustment process. In order to understand the consistency of frequency in a timely manner, a sampling station should be added in the sealing welding process to check the condition of fine-tuning after welding, especially to find the fine-tuning range or fine-tune the individual difference. When analyzing the cause, it must be considered whether the time of each batch of products flowing in the process is about the same, and the shorter the better, this also has a great impact on the DLD characteristics of the product.

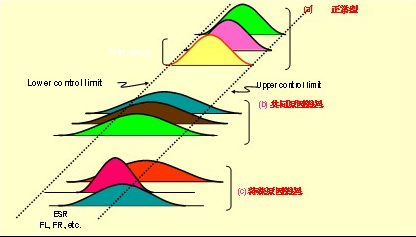

常温电阻特性主要是中心值与稳定性。电阻中心值与控制上限的距离与产品的合格率息息相关,在测试系统中可以用平均值代替中心值,一般要求产品平均值是控制上限的50%左右。做制程改善时重点关注点胶与污染。

The room temperature resistance characteristics are mainly the center value and stability. The distance between the resistance center value and the control upper limit is closely related to the product qualification rate. In the test system, the average value can be used instead of the center value. Generally, the product average value is about 50% of the upper control limit. Focus on dispensing and contamination when making process improvements.

芯片不良在电阻大这一不良项中出现次数会比较多,特别是新的芯片供货商或开发新频点时。

Chip failures occur more frequently in the case of large resistors, especially when new chip suppliers or new frequency points are developed.

通常产品在常温下的电阻要比频率更稳定,其变化量更容易控制在±0.5Ω以内,一般只有高频产品或3RD产品会出现此类问题,如果产品有此类现象往往归在可靠性中分析。

Generally, the resistance of the product at room temperature is more stable than the frequency, and the amount of change is more easily controlled within ±0.5 Ω. Generally, only high-frequency products or 3RD products may have such problems. If the product has such a phenomenon, it is often attributed to reliability. In the analysis.

激励功率相关性主要是考察产品在不同激励功率下的频率或电阻及其变化量,目前SMD产品设定的最小激励功率一般是0.01uW,最大激励功率一般是200 uW,20M以上的优良产品DLD2和FDLD应小于1,12M左右的低频产品DLD2特性稍差,但其中心值也应低于8Ω。产品DLD出问题时的分析图请参照产品电阻大的分析图,但有一点应特别引起重视—产品封焊前在制程中的流动速度越快越好,各工序产出应尽量平衡,减少物料在各工序等待时间。

The excitation power correlation is mainly to investigate the frequency or resistance of the product under different excitation power and its variation. At present, the minimum excitation power set by SMD products is generally 0.01uW, the maximum excitation power is generally 200 uW, and the excellent product DLD2 above 20M. The low-frequency product DLD2 with FDLD should be less than 1,12M is slightly inferior, but its center value should also be lower than 8Ω. For the analysis of the product DLD, please refer to the analysis chart of the product resistance, but one point should be paid special attention. The faster the flow rate in the process before the product is sealed, the better the output should be balanced and the materials should be reduced. Waiting time in each process.

DLD2:电阻激励功率相关性(RRMAX — RRMIN)。单位:欧姆Ω

RLD2:激励功率范围内的最大电阻。

FDLD:频率激励功率相关性(FLMAX ——FL MIN)

DELF(FLR):串并联间隔(FL—Fr)

DLDH2:不同激励功率下的电阻迟滞(同一激励功率点前后两次测试的ESR最大差值)。

其次是贴片晶振产品的温度特性:产品的温度特性是指产品在不同温度下的电性能变化情况,优良产品的温度特性呈光滑的三次曲线(AT切)或二次曲线(BT切),与理论曲线非常相似。主要影响因素是芯片的切型与切割角度,在石英芯片这一节中已有相关介绍,另外芯片加工过程的平面度(高频)和修边情况(低频)也会影响产品的温度特性。制程中芯片污染,电极偏位等也会对产品的温度特性造成影响。

再然就是产品的可靠性(信赖性):产品的可靠性可以通俗的理解为:产品生产完成后,不会因常规的搬运,储存而使其性能受影响,不会因客户的焊接,清洗和封装等各种使用条件而影响性能。产品的可靠性可以通过各种可靠性试验来衡量,目前常见的可靠性试验有:

高温储存试验 125℃±10℃;1000H±24H

温度循环试验 T1 = -55℃±10℃ T2= 125℃±10℃;循环次数10次。(温度转换约30分钟)

温度冲击试验 T1 = -55℃±10℃ T2= 125℃±10℃;循环次数10次。(温度转换时间5秒)

恒温恒湿试验 TC 85±10℃ H 85% ;1000H±24H

可焊性(焊锡)试验 230±10℃;3 s

耐焊接试验 260±10℃;10 s

跌落试验 75 cm;3 次。

振动试验 频率10 Hz — 2000 Hz;振幅 1.5 mm;每方向 40 分钟。

老化率试验 TC 85±10℃;300 H

寿命试验(MTBF);85℃or125℃;1000H;利用公式及失效产品数计算出产品模拟寿命。

在以上十项试验中,恒温恒湿试验主要考察产品储存时会不会出现外观变异,是否会影响焊接,可焊性(焊锡)试验主要考察产品在客户端使用时能否顺利焊接到电路板上,只要原材料不出问题,产品在制程中不严重超温,无严重污染就不会有问题。

其余试验主要是通过对比试验前后产品的电性能变化情况来衡量产品的可靠性,其中高温储存试验,老化率试验和寿命试验考察产品的储存条件与储存时间;温度循环试验和温度冲击试验考察产品在客户端使用时对温度变化的耐受情况。产品在制程中无明显污染,银层牢固,封焊时露点符合要求,检漏无漏气就能满足要求。

跌落试验考察产品受机械力冲击时的耐受情况,跌落试验不合格应分两各情况来处理,一是芯片破裂造成不良(高频),应检查导电胶选用是否正确(较柔),底胶是否足够,芯片在搭载时是否过低;另一各情况是脱胶,或称胶点松动,应检查烤胶工艺是否有问题,芯片上下胶量是否足够,上下胶连接处胶量是否饱满。

In the process of using crystal or crystal welding, there are many problems encountered. Welding problems sometimes cannot be soldered. Crystal products can't be hanged on the board. Soldering and false soldering are all possible. The normal operation of the plate, or the mistakes in the welding process, cause the crystal to deviate too much after welding the board.

在这里,泰河电子为大家整理了一份关于晶振产品的产品特性以及影响产品特性的因素,以供大家参考使用.喜欢的可以收藏起来后续再看.

Here, Taihe Electronics has compiled a product characteristic for the crystal product and factors affecting the product characteristics for your reference. You can collect it and follow it later.

首先是我们比较关心的常温产品特性:常温产品特性有时也称为室温产品特性,一般是指产品在环境温度为25℃,相对湿度为50%左右时所测量出来的电性能参数,主要是频率,电阻,激励功率相关性及电容比等指标。

First of all, we are concerned about the characteristics of normal temperature products: normal temperature product characteristics are sometimes called room temperature product characteristics, generally refers to the electrical performance parameters measured when the product temperature is 25 ° C, relative humidity is about 50%, mainly frequency , resistance, excitation power correlation and capacitance ratio indicators. 常温下石英晶振产品的频率主要是观察其稳定性与一致性。稳定性是相对于单个产品而言,一方面要求产品在测试仪上重复测试时,频率变化量要小,好产品频率变化量可以小于±0.5ppm,与产品频率高低及TS大小有关,一般情况下,频率越高变化量越大,TS越大变化量越大,测量指标一般是FL,若是FR则不存在TS的问题;另一方面要求产品在电路中工作时不出现频率漂移,也就是说产品频率不要跑到几百甚至几千ppm去,一般情况下只有高频(27M以上)产品才会有这个问题,尤其是3RD产品。

The frequency of the product at room temperature is mainly to observe its stability and consistency. The stability is relative to a single product. On the one hand, when the product is repeatedly tested on the tester, the frequency change is small, and the good product frequency variation can be less than ±0.5ppm, which is related to the product frequency and TS size. The higher the frequency, the larger the amount of change, the larger the TS is, the larger the change is. The measurement index is generally FL. If it is FR, there is no TS problem. On the other hand, the product does not have frequency drift when working in the circuit. Say that the product frequency should not go to hundreds or even thousands of ppm. Under normal circumstances, only high frequency (27M or more) products will have this problem, especially 3RD products.

如果频率不稳定,偏移的幅度上百ppm或同时伴有C0偏小现象,应考虑胶点是否松动。

If the frequency is unstable, the amplitude of the offset is hundreds of ppm or accompanied by a small C0 phenomenon, it should be considered whether the glue point is loose.

对于一条相对成熟的生产线来说,产品在常温下的频率稳定性一般不会出现问题,比较常见的是产品的一致性(散差),尤其是高频的小公差产品一致性往往不如人意。一致性考虑是多个产品的频率公差,在测试系统中,观察FL的正态分布图可以很直观的了解产品的一致,也可以使用仪器测试系统中的CPK计算功能,通过CPK来衡量产品的一致性。

For a relatively mature production line, the frequency stability of the product at normal temperature is generally not a problem, the more common is the consistency of the product (difference), especially the high-frequency small tolerance product consistency is often unsatisfactory. Consistency consideration is the frequency tolerance of multiple products. In the test system, observing the normal distribution map of FL can be very intuitive to understand the consistency of the product, and can also use the CPK calculation function in the instrument test system to measure the product by CPK. consistency.

Due to the incorrect baking time or temperature, the frequency dispersion will be large, but the probability of occurrence is small. The large dispersion of the frequency caused by the chip is generally reflected in the fine adjustment process. In order to understand the consistency of frequency in a timely manner, a sampling station should be added in the sealing welding process to check the condition of fine-tuning after welding, especially to find the fine-tuning range or fine-tune the individual difference. When analyzing the cause, it must be considered whether the time of each batch of products flowing in the process is about the same, and the shorter the better, this also has a great impact on the DLD characteristics of the product.

常温电阻特性主要是中心值与稳定性。电阻中心值与控制上限的距离与产品的合格率息息相关,在测试系统中可以用平均值代替中心值,一般要求产品平均值是控制上限的50%左右。做制程改善时重点关注点胶与污染。

The room temperature resistance characteristics are mainly the center value and stability. The distance between the resistance center value and the control upper limit is closely related to the product qualification rate. In the test system, the average value can be used instead of the center value. Generally, the product average value is about 50% of the upper control limit. Focus on dispensing and contamination when making process improvements.

芯片不良在电阻大这一不良项中出现次数会比较多,特别是新的芯片供货商或开发新频点时。

Chip failures occur more frequently in the case of large resistors, especially when new chip suppliers or new frequency points are developed.

通常产品在常温下的电阻要比频率更稳定,其变化量更容易控制在±0.5Ω以内,一般只有高频产品或3RD产品会出现此类问题,如果产品有此类现象往往归在可靠性中分析。

Generally, the resistance of the product at room temperature is more stable than the frequency, and the amount of change is more easily controlled within ±0.5 Ω. Generally, only high-frequency products or 3RD products may have such problems. If the product has such a phenomenon, it is often attributed to reliability. In the analysis.

激励功率相关性主要是考察产品在不同激励功率下的频率或电阻及其变化量,目前SMD产品设定的最小激励功率一般是0.01uW,最大激励功率一般是200 uW,20M以上的优良产品DLD2和FDLD应小于1,12M左右的低频产品DLD2特性稍差,但其中心值也应低于8Ω。产品DLD出问题时的分析图请参照产品电阻大的分析图,但有一点应特别引起重视—产品封焊前在制程中的流动速度越快越好,各工序产出应尽量平衡,减少物料在各工序等待时间。

The excitation power correlation is mainly to investigate the frequency or resistance of the product under different excitation power and its variation. At present, the minimum excitation power set by SMD products is generally 0.01uW, the maximum excitation power is generally 200 uW, and the excellent product DLD2 above 20M. The low-frequency product DLD2 with FDLD should be less than 1,12M is slightly inferior, but its center value should also be lower than 8Ω. For the analysis of the product DLD, please refer to the analysis chart of the product resistance, but one point should be paid special attention. The faster the flow rate in the process before the product is sealed, the better the output should be balanced and the materials should be reduced. Waiting time in each process.

DLD2:电阻激励功率相关性(RRMAX — RRMIN)。单位:欧姆Ω

RLD2:激励功率范围内的最大电阻。

FDLD:频率激励功率相关性(FLMAX ——FL MIN)

DELF(FLR):串并联间隔(FL—Fr)

DLDH2:不同激励功率下的电阻迟滞(同一激励功率点前后两次测试的ESR最大差值)。

其次是贴片晶振产品的温度特性:产品的温度特性是指产品在不同温度下的电性能变化情况,优良产品的温度特性呈光滑的三次曲线(AT切)或二次曲线(BT切),与理论曲线非常相似。主要影响因素是芯片的切型与切割角度,在石英芯片这一节中已有相关介绍,另外芯片加工过程的平面度(高频)和修边情况(低频)也会影响产品的温度特性。制程中芯片污染,电极偏位等也会对产品的温度特性造成影响。

再然就是产品的可靠性(信赖性):产品的可靠性可以通俗的理解为:产品生产完成后,不会因常规的搬运,储存而使其性能受影响,不会因客户的焊接,清洗和封装等各种使用条件而影响性能。产品的可靠性可以通过各种可靠性试验来衡量,目前常见的可靠性试验有:

高温储存试验 125℃±10℃;1000H±24H

温度循环试验 T1 = -55℃±10℃ T2= 125℃±10℃;循环次数10次。(温度转换约30分钟)

温度冲击试验 T1 = -55℃±10℃ T2= 125℃±10℃;循环次数10次。(温度转换时间5秒)

恒温恒湿试验 TC 85±10℃ H 85% ;1000H±24H

可焊性(焊锡)试验 230±10℃;3 s

耐焊接试验 260±10℃;10 s

跌落试验 75 cm;3 次。

振动试验 频率10 Hz — 2000 Hz;振幅 1.5 mm;每方向 40 分钟。

老化率试验 TC 85±10℃;300 H

寿命试验(MTBF);85℃or125℃;1000H;利用公式及失效产品数计算出产品模拟寿命。

在以上十项试验中,恒温恒湿试验主要考察产品储存时会不会出现外观变异,是否会影响焊接,可焊性(焊锡)试验主要考察产品在客户端使用时能否顺利焊接到电路板上,只要原材料不出问题,产品在制程中不严重超温,无严重污染就不会有问题。

其余试验主要是通过对比试验前后产品的电性能变化情况来衡量产品的可靠性,其中高温储存试验,老化率试验和寿命试验考察产品的储存条件与储存时间;温度循环试验和温度冲击试验考察产品在客户端使用时对温度变化的耐受情况。产品在制程中无明显污染,银层牢固,封焊时露点符合要求,检漏无漏气就能满足要求。

跌落试验考察产品受机械力冲击时的耐受情况,跌落试验不合格应分两各情况来处理,一是芯片破裂造成不良(高频),应检查导电胶选用是否正确(较柔),底胶是否足够,芯片在搭载时是否过低;另一各情况是脱胶,或称胶点松动,应检查烤胶工艺是否有问题,芯片上下胶量是否足够,上下胶连接处胶量是否饱满。

正在载入评论数据...

相关资讯

- [2023-07-12]康纳温菲尔德推出符合Stratum3E...

- [2023-06-26]选择石英晶体要了解的必要参数,...

- [2023-06-25]艾伯康公司发布连续电压有源晶振...

- [2021-01-18]今日主题:什么样性能的石英晶振...

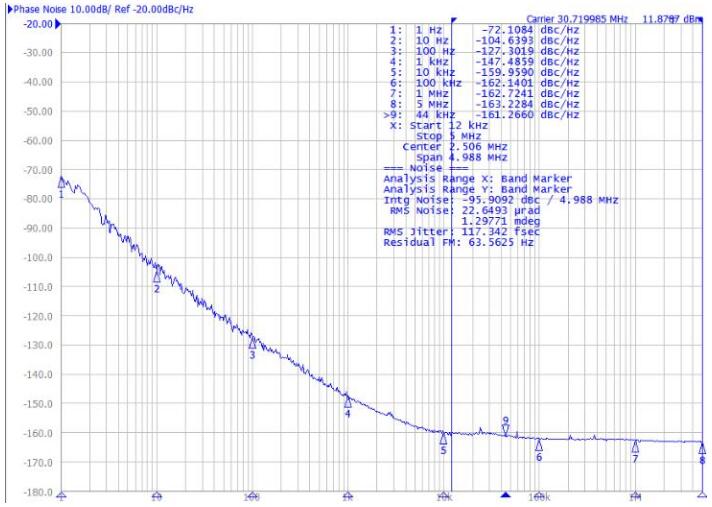

- [2021-01-13]是什么原因造成晶振相噪恶化?都...

- [2020-12-09]干货干货!爱普生旗下SG-8018系列...

- [2020-09-08]石英Crystal工作原理是怎样的,这...

- [2020-09-01]Oscillator的制造流程究竟是怎样...